Get the Best ERP Software for Logistics Industry. Improve Your Shipping and Supply Chain with Customizable Logistics Software.

Optimize your Warehouse

Real-time inventory management with advanced features like serial tracking, lot control, packaging, reservation strategies, cycle counting, KPIs, and more.

Instant inventory lookup: quickly locate products across multiple warehouses or companies.

Instant inventory lookup: quickly locate products across multiple warehouses or companies.

Locations

Create and manage specific storage locations, like shelves, aisles, cold storage rooms, and pallet racks.

Putaway Rules

Automatically route products to ideal storage locations based on real-time capacity (storage categories), product storage needs, and picking accessibility.

Operations

Create dedicated locations to receive products, sort, pack, and other warehouse operations.

Smart Removal

Choose product removal strategies (FIFO, FEFO, nearest available zone, LEFO) and streamline picker paths with the right picking method (single, batch, cluster, wave).

Manage incoming shipments with vendor-provided arrival dates and automatic unit of measure conversion for received quantities. (e.g. buy in tons and sell in kg.)

Receipts

Return

Set predefined routes for return condition assessment, refurbishing, restocking, or disposal. When integrated with the Accounting app, the returned product's updated inventory valuation immediately hits your books.

Create smart automatic batches based on shipping carriers, serial numbers, specific quantities, and total weight for picker convenience. If stock is insufficient, the option to create a backorder is available.

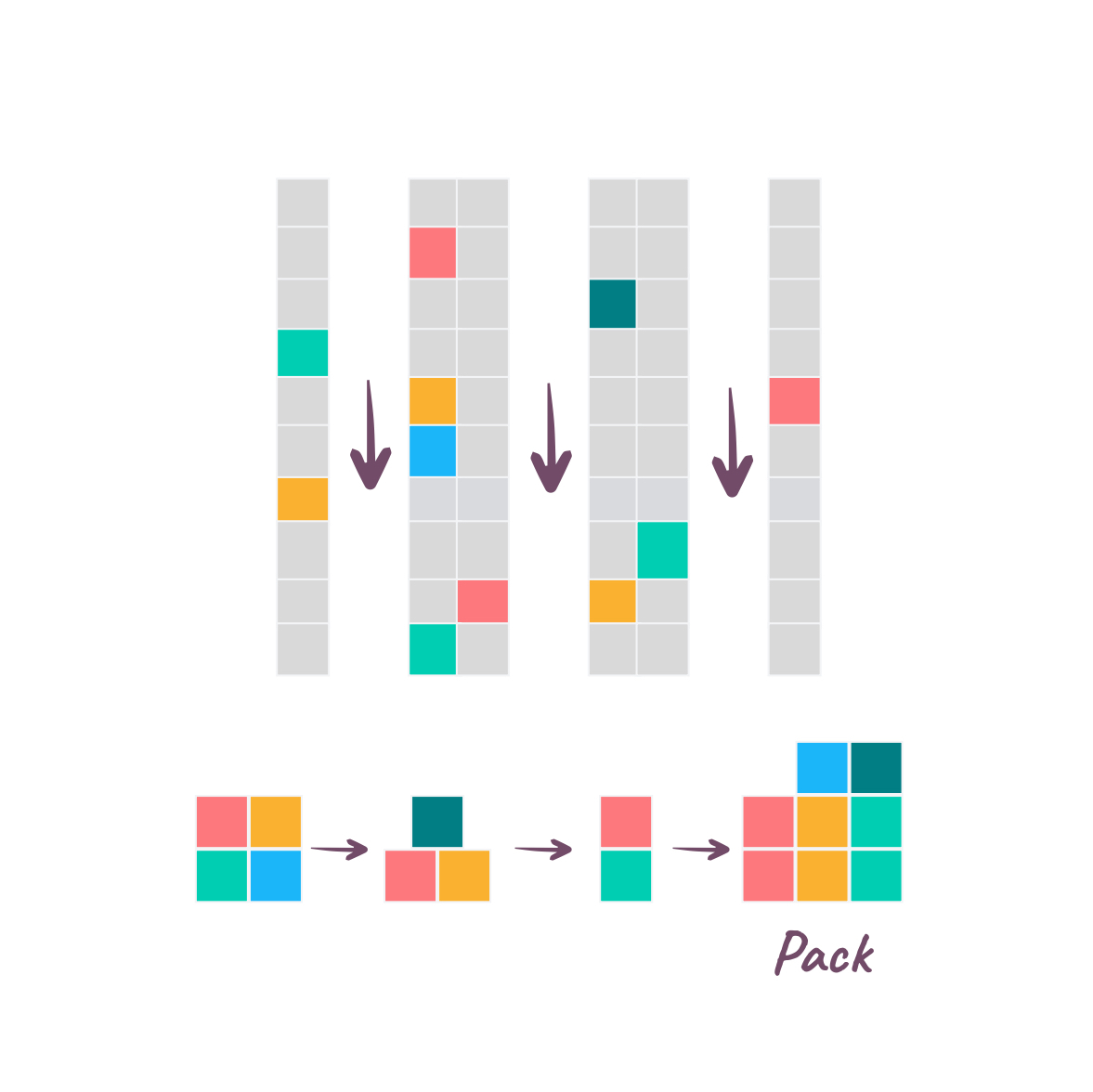

Pick & Pack

Scrap products in just a few clicks and get clear reports on scrap: their costs, reasons and volumes

Scrap

Schedule recurring stock counts on vital storage locations, products, or lots to keep inventory up to date all the time.

Inventory adjustment